3MU Check sheet | Details of MURA, MURI & MUDA | Download

Last updated on October 5th, 2024 at 10:16 am

3MU Check sheet | Details of MURA, MURI & MUDA:

Hi Readers! Today we will discuss here details on MURA, MURI & MUDA. you can download our free template of the 3MU check sheet from the below links. The 3MU’s are MURA (Discrepancy), MURI (Strain), MUDA Waste).

DOWNLOAD-3MU Check Sheet. (MUDA).

The 3MU can be applied in the below fields;

- Method of operation.

- Manpower.

- Process involved.

- Technique.

- Facilities.

- Time.

- Jigs & Tools.

- Materials.

- Inventory.

- Production Volume.

- Place.

- Way of thinking.

Details of MURA, MURI & MUDA:

| MURA | MURI | MUDA |

| Unevenness, Discrepancy, Irregular | Unreasonableness, Strain, Overdoing, Overburdened | Unusefulness, Waste. |

| Any variation leading to unbalanced situations. | A system, facility, or process designed beyond the physical capacities of equipment/ workforce | Activities which does not add value. |

MUDA: Waste, Unusefulness;

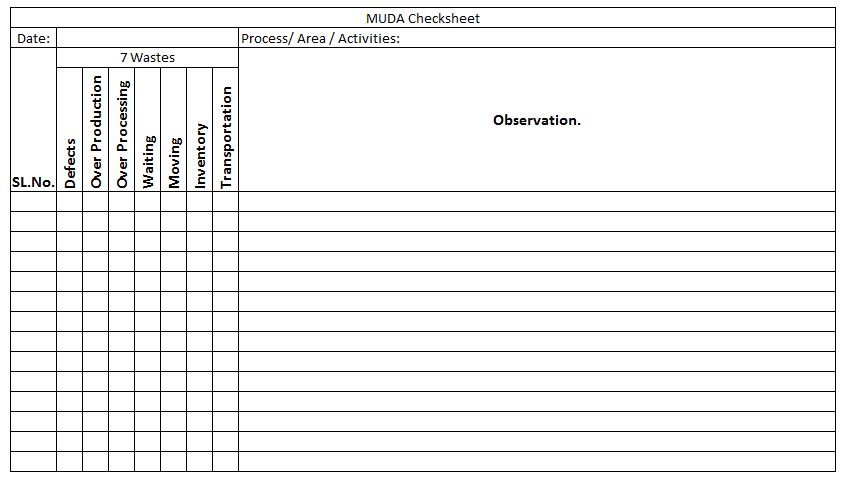

An any activities that do not add value w.r.t the customer perspective, presently in industry; elimination of waste (MUDA) is the big challenge. Many lean tools are there that you can implement it to deduce the MUDA. Value stream mapping is the one of the popular tools that basically used in many industries. But the identification of waste is a big job. The common 7 wastes are;

- Defects: The Defective product is total waste.

- Overproduction: Production more than demand or less than demand is a loss.

- Over Processing: Rework, Repair, Rechecking is a waste of time and money.

- Waiting: Waste of time, and money.

- Moving: The movement of goods within or outside is waste.

- Inventory: Unfinished goods, R/M, BOP add no value.

- Transportation: Unnecessary transfer of goods is waste.

Considering with above points we have prepared a sample MUDA Checklist for your ready reference. DOWNLOAD the MUDA Check sheet.

MURA: Unevenness, Discrepancy, Irregular;

MURA can exist when the workflow is out of balance.

MURI: Unreasonableness, Strain, Overdoing, Overburdened;

A system, facility, or process designed beyond the physical capacities of equipment/ workforces.

How to eliminate 3MUs?

The MURA (Unbalanced Process) can lead to an overburden on the workforce or equipment which may cause later on all kinds of non-value-added activities (MUDA). So to eliminate the 3MUs you have to give more focus on Value stream mapping, Process layout design, and 5’S, Visual standard, Kaizen, Process feasibility analysis, and Process variation.

Example:

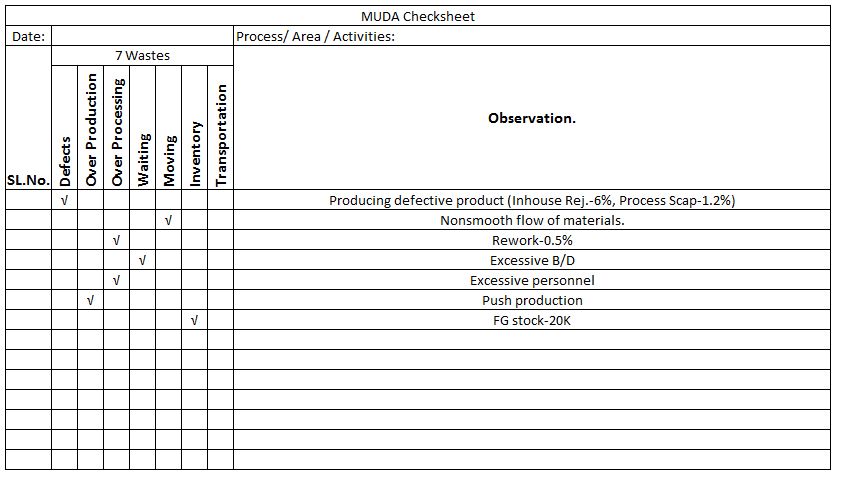

You can audit your respective area by using our 3MU-MUDA Check Sheet, Similarly, we have done this in the manufacturing unit and found some observations, same mentioned in below for your easy understanding.

We have taken some initiatives against the above findings (Observation) to eliminate the MUDA in the process as;

| Observations | Management Initiative |

| Producing defective product | TQM, QA |

| The Nonsmooth flow of materials | KANBAN, JIT, PPC |

| Rework-0.5% | TQM, QA |

| Excessive B/D | TPM |

| Excess Production | Pull Production, PPC |

| FG Stock-High | Inventory Management, World class Supply chain Management |

Useful Articles:

4M Checklist Template |Free Download Format

SPC Format |DOWNLOAD Excel Template of SPC Study

why why analysis methodology | 5-why analysis step by step guide

How to measure process capability (Cp & Cpk)? Download Excel Template

Error Proofing Understanding & Implementation of IATF 16949 Clauses 10.2.4

Pareto Chart Example of Manufacturing Units

Thank you for reading…keep visiting Techiequality.Com

Popular Post: