What is Quality 4.0 | What Type of Skill Set Needs to be Developed as an Employee

Last updated on January 1st, 2024 at 04:14 pm

What is Quality 4.0 | What Type of Skill Set Needs to be Developed as an Employee

Hello readers! Today we will be discussing on an important topic which is nothing is called Quality 4.0. In this digital era, both the manufacturing industry and its functional departmental activities are going to transit to the next Digital level. Quality 4.0 is also called 4th revolution smart quality. The most important thing is the new challenges to both employees and employers. Definitely, we will cover both important things over here. Just read the complete articles.

What is Quality 4.0:

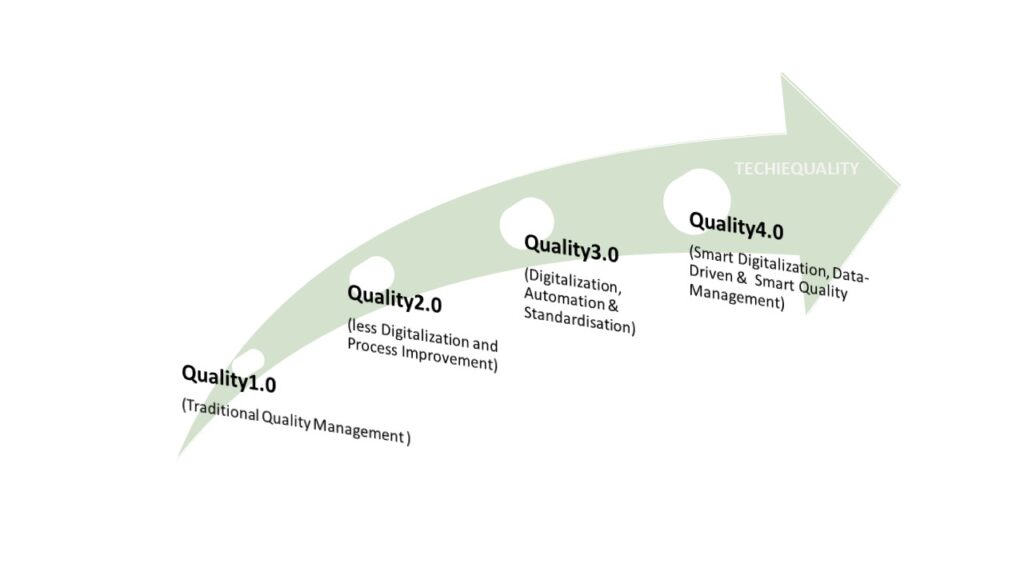

Before directly going to the topic “Quality 4.0”. I would like to tell you about the revolution of Quality from 1.0 to 4.0. then we will discuss the complete subject of Quality 4.0 and how it would affect both employees and employers of manufacturing industries.

In the above picture, it has been clearly mentioned that Quality 1.0 to Quality 4.0. As we know there is industry 4.0 is rapidly penetrating in the industry. Similarly, Quality 4.0 is part of Industry 4.0.

Nothing is permanent in this world; accordingly, revolution, improvement, and innovation are always there in the industry it could be a product revolution, process, or industry revolution. Revolution is the dynamic system for better quality, product, service and cost reduction, revenue enhancement, etc. so both employee and employer should adopt the new challenges with respect to a new revolution. Data and smart operations are the future of any type of organization. So, quality 4.0 is also giving more emphasis on Smart digitalization, Data-driven, and smart quality management.

Quality 4.0 is a concept/method/ smart activity that builds upon the principles of Industry 4.0, Q4.0 is the integration of digital technologies, automation, and data exchange in manufacturing and industrial processes. Quality 4.0, similarly, its focuses on technologies for Quality assurance activities within industries mainly on manufacturing units.

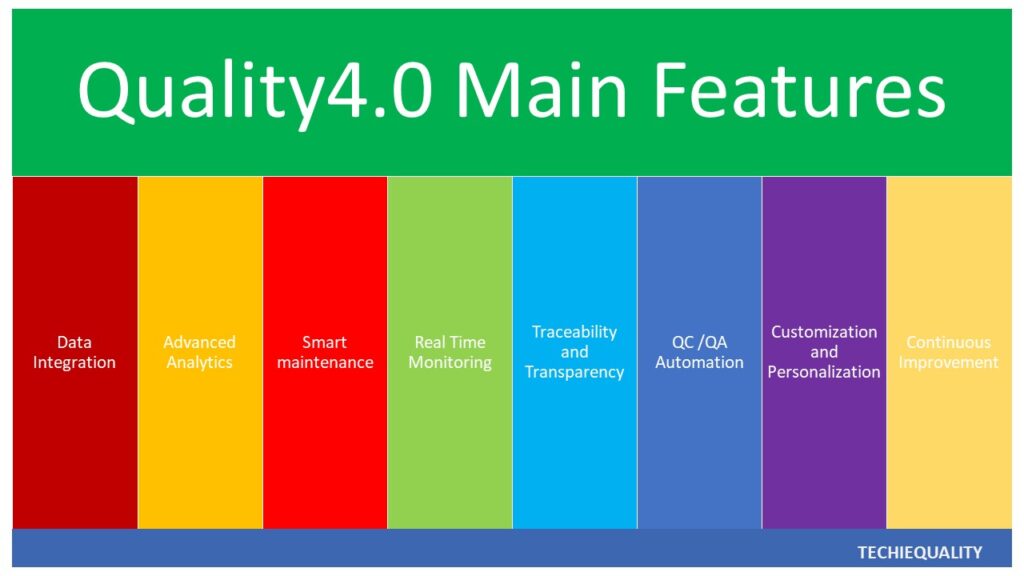

Quality4.0 Main Features:–

As you can see in the above image, the main features/structures of Quality4.0 are mentioned and these are

- Data Integration

- Advanced Analytics

- Smart Maintenance

- Real-Time Monitoring

- Traceability & Transparency

- QC/QA Automation.

- Customization & Personalization

- Continuous Improvement.

Let us understand details on the above main features with examples.

Data Integration:

Nowadays many organizations use traditional methods for data collection and data recording on a manual basis, for example, many organizations still do manual inspections for getting the data/measurement/ Dimension/ parameter reading/ process & product characteristics checking. But Quality4.0 relies on the integration of data from several sources within manufacturing activities through advanced smart devices like sensors, cameras, automatic equipment, and software integration. Using machine learning and artificial intelligence in machines as advanced programable software for data collection and advanced-level interpretation.

Data is more important for further analysis and decision-making in manufacturing industries. So, data Integration is a very crucial activity in manufacturing industries.

Advanced Analytics:

Data analysis and result interpretation are the major activities in manufacturing industries. Analysis and interpretation can be done using advanced analytics including artificial intelligence and machine learning. A machine or device can automatically do these activities using artificial intelligence.

Smart Maintenance:

Maintaining the health of machines is a major challenge in manufacturing industries due to the time factor, customer demand, and limited resources. Machine health can directly affect product quality. So both predictive and preventive maintenance are important, but think about the automatic system where the machine itself sends you the health alert to your mobile or laptop through IOT or any other smart digital way then it will be very useful to maintain the condition of the machine and tools.

Real-Time Monitoring:

Real-time monitoring of production process, quality parameters, and product & process characteristics to detect and address quality issues. And then analyzing it for result interpretation can help to minimize the non-conformity.

Traceability and Transparency:

Real-time traceability and back path traceability can be easily done through the quality4.0 system. Many technologies like blockchain and other tools are used in supply chain management for traceability and transparency purposes.

QC/QA Automation:

Automatic inspection and process control can be done by using Automation technologies like robots, MVS (machine vision systems), Cameras, sensors, and automatic poka-yoke systems for more efficient and accurate process control.

Continuous Improvement:

Advanced data analysis and perfect interpretation through automation systems can be always helpful for continuous improvement.

There are big and small challenges in every revolution, similarly in Quality4.0 there are many challenges but we will be discussing only some major key challenges of implementing Q4.0.

Major Key Challenges of Quality 4.0

- Confirming data correctness, safety, and compatibility across different systems and equipment can be a significant difficulty.

- As we know data are more important things for any organization, so protecting and preventing data breaches is crucial. This is one of the major key challenges for organizations.

- An initial investment in training, software, devices, and technology is also a big challenge for some companies, especially for small categories of industries or organizations.

- Operating the new technology, including quality4.0, AI, Machine learning, and Data Science required trained operators and new skills.

- Cultural and process changes related challenges due to the implementation of Quality4.0

- Compliance obligation challenges.

- Ensuring Automatic system functioning, maintenance, and accuracy of data.

How to Implement Quality 4.0

To implement the Q4.0 in your organization, you have to prepare the milestone or roadmap of the Q4.0 implementation plan. Details are given below;

Here we will learn the process of implementation of Quality4.0 with a practical example for manufacturing industries, let us say you are going to implement one of the popular projects of Quality4.0, which is real-time monitoring and Quality control of products at the production line. Just follow the below steps for implementation (these are not limited to).

- Understand the needs of the company or organization: Think about the point that your organization wants to achieve through Q4.0, for example, real-time monitoring of data, robotics, etc.

- Make strategy or Q4.0 plan: now it’s time to prepare a plan with a responsible and target date.

- Technology and Infrastructure: as we know that, we are going to convert the traditional activities to a digitally controlled process, so technology, software, automatic system, AI, and machine learning are required to install it to successfully implement the Q4.0.

- Data integration: First of all, you have to develop an automatic system to collect the data through integration from various sources line sensors, visual systems, cameras, robotics, etc. within the manufacturing operations.

- AI, ML, and Data Analytics: Implement the AI, ML, and Data analytics software and technology for data analysis, pattern, chart preparation, and result interpretation.

- Real-time Monitoring: Installed the automatic quality control system for real-time monitoring.

- Automation of Quality assurance workflow.

- E&T

- Change management.

- Data security and privacy.

What type of Skills set needs to be developed as an Employee?

To manage and operate the quality4.0’s new technology, an organization or company requires workforces with some range of skills like;

- Data Analytics and Science.

- Knowledge of AI and ML

- Cybersecurity, IT, IoT, etc.

- Automation

- Robotics

- Statistics, QC and QC, Decision-making ability, Result interpretation, etc.

Benefits of Quality 4.0

Following are some key benefits but these are not limited to;

- Reduced Defects and waste

- Enhanced customer satisfaction

- Improved product quality

- Efficiency and effectiveness improvement

- Data-driven decision making

- Real-time monitoring

- Quick quality issue resolution

- Competitive advantage

- Scalability

- Continuous Improvement

Useful Post:

6-Sigma Project Charter Template.

Why why analysis excel template.

QA/ QC / QMS / Six sigma template

More on TECHIEQUALITY