8D Report | Free Download of 8D Template or Format

Last updated on October 5th, 2024 at 10:31 am

8D Report | Free Download of 8D Template

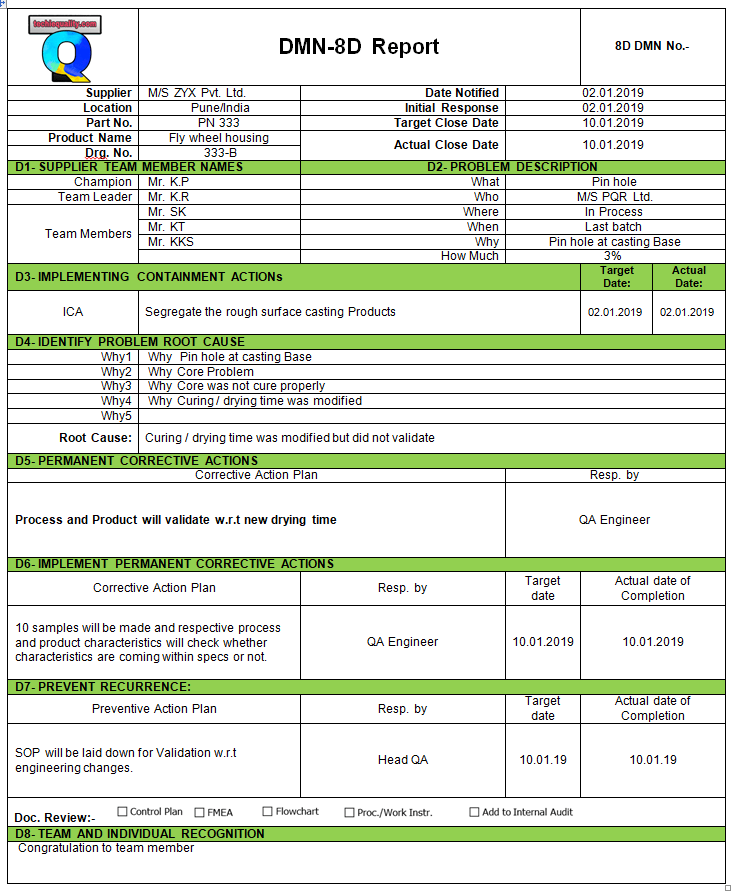

8D Report, Format, or Template is ready for you just click on Download. Here we will describe the 8D Report with a Manufacturing related example.

DOWNLOAD-(8D-DMN Report Template /format /form in Excel Format)

Basic Info. of 8D Report:

It’s a Problem-solving approach followed by Eight Critical Steps. This is used to provide excellent guidelines to identify the Root cause of The Problem or Issue. Moreover, an 8D approach is used to implement the solutions to prevent recurring problems. It was first used in the automotive industry.

Generally, Customer asks their Suppliers / Vendors / External Providers to submit the 8D Report as of and when they find the Defective material at their ends as BOP, Raw Materials, etc.

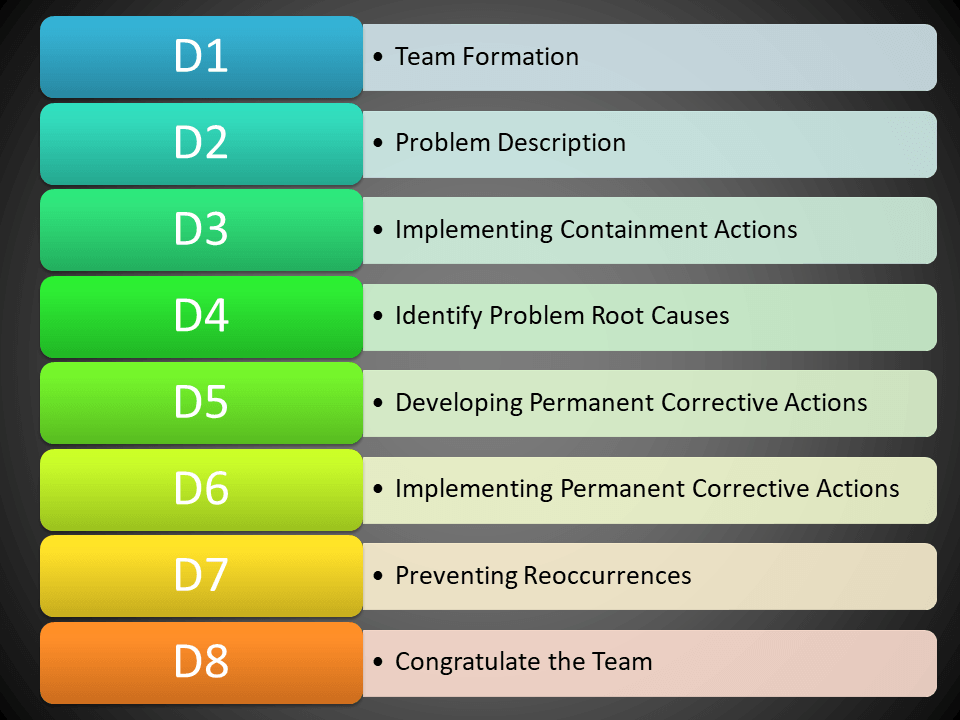

Eight Steps of 8D Report:

- Team Formation

- Problem Description

- Implementing Containment Actions

- Identify Problem Root Causes

- Developing Permanent Corrective Actions

- Implementing Permanent Corrective Actions

- Preventing Re-occurrences

- Congratulating the Team

D1:- Team formation

A Cross-Functional team with multi-skilled Members needs to be selected.

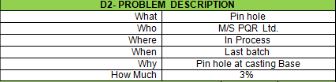

D2:- Problem Description

Describe the Problem in the form of 5W 2H as Who, What When, Where, Why, How, and how much.

D3:- Containment actions

Temporary Action needs to be implemented until a permanent solution is implemented.

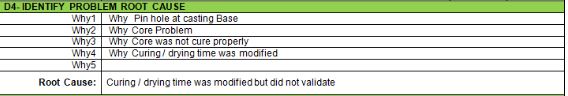

D4:- Identify Problem Root Cause

After the implementation of Containment Action, We have to do the Root Cause Analysis to find out the Root Cause for the implementation of the

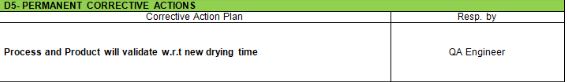

D5:- Developing permanent corrective actions

After getting the Root Cause of a Problem, we have to prepare an Action plan for the Possible solution. From there Permanent Corrective actions need to be selected.

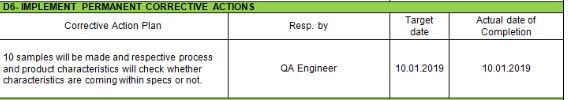

D6:- Implementing permanent corrective actions

As soon as possible, Developed Permanent Corrective Actions need to be implemented. Implementation Plan / Activity Plan / Milestone Plan will help you better monitor and track the status of Activities.

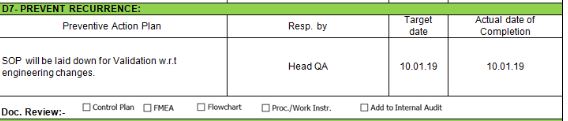

D7:- Preventive Re-occurrences

Here Preventive Action needs to be taken to minimize the Reoccurrences. In doing so, a review of the Management system, SOP, Control plan, FMEA, and Risk Management, so that it will prevent the Reoccurrence.

D8:- Congratulating the team

Now, it’s time to congratulate the Recognize your team for the joint effort. It is the most important step among All steps, which will help you to improve the moral part of people’s engagement.

Example-1 Customer asked 8D report for casting pin-hole issue.

Details of the above Example:

D-1: Supplier team member name: Organization is supposed to form a team with a Team leader and Champion.

D-2: Problem Description: You may describe the problem in a 5W1H manner or 5W2H.

D-3: Implementing Containment action:

Immediate action needs to be taken so that the defective product will not be dispatched to the customer.

D-4: RCA: You can find out the Root cause by why-why analysis, hypothesis testing, etc.

D-5: Corrective Action:

Action to eliminate the root cause of the problem.

D-6: Implement CA: here in this stage we have to implement the action of the corrective action plan.

D-7: Preventive action:

Action to eliminate the potential cause of the problem. according to the new ISO 9001:2015 standard requirement, Risk analysis is there. but in the above example we have mentioned the PA as;

Example-2:

We have discussed here another practical manufacturing example for your better understanding, For Example, At the customer end, 80% of the last consignment material found a machining problem, so the customer asked their supplier to submit the 8D report. That 8D report has been described below, kindly go through it to know the details.

Illustration of above example-2:

D-1- SUPPLIER TEAM MEMBER NAMES: There should be a team member, leader, and champion. so choose team members smartly covering the several functions as CFT, so that your team’s technical strength will be enhanced.

D-2- PROBLEM DESCRIPTION:

This is the vital step where you have to confirm the problem and similarly need to describe it.

D-3- IMPLEMENTING CONTAINMENT ACTIONS: Take immediate action so that your customer will not receive a non-conforming product/ material /item. In the above example, the supplier has stopped the consignment of the mix-up item ( Good and NG material) to the customer.

D-4- IDENTIFY THE PROBLEM ROOT CAUSE:

You can use several techniques or tools to find out the root cause, the commonly used technique is the why-why analysis.

D-5- PERMANENT CORRECTIVE ACTIONS: An action to eliminate the root cause of a problem, so whatever the RC will be found by root cause analysis then you have to take action on it. SO here covering the CAPA part is the important part.

D-6- IMPLEMENT PERMANENT CORRECTIVE ACTIONS & D-7- PREVENT RECURRENCE:

Refer to CAPA.

D-8- TEAM AND INDIVIDUAL RECOGNITION: Congratulations to your team members.

FAQ:

What are the 8D steps?

The 8D is [1] Team Formation [2] Problem Description [3] Implementing Containment Action [4] Identify Problem Root Cause [5] Developing Permanent Corrective Action [6] Implementing Permanent Corrective Action [7] Preventing Reoccurrence [8] Congratulate the Team.

What is the difference between CAPA and 8D?

The CAPA and 8D are problem-solving approaches. During the RCA (Root cause analysis) of the problem, we generally develop the Action plan and represent it in different and different formats/templates like CAPA, 8D, G10, etc. The main objective or purpose of both methods is to develop the action plan, implement the action plan, and measure the effectiveness of the action plan. I meant to say that both are problem-solving approaches/ methods.