8D Report Example | Download Case Study Report:

Last updated on November 16th, 2024 at 08:36 am

How to fill up 8D Report Template |8D Report Example:

Hi. ! Reader, today we will discuss the 8D Report Example, case study, and How to fill up the 8D Report Template, if you have not yet downloaded the 8D Template then download the Format /template /form by clicking on the below link.

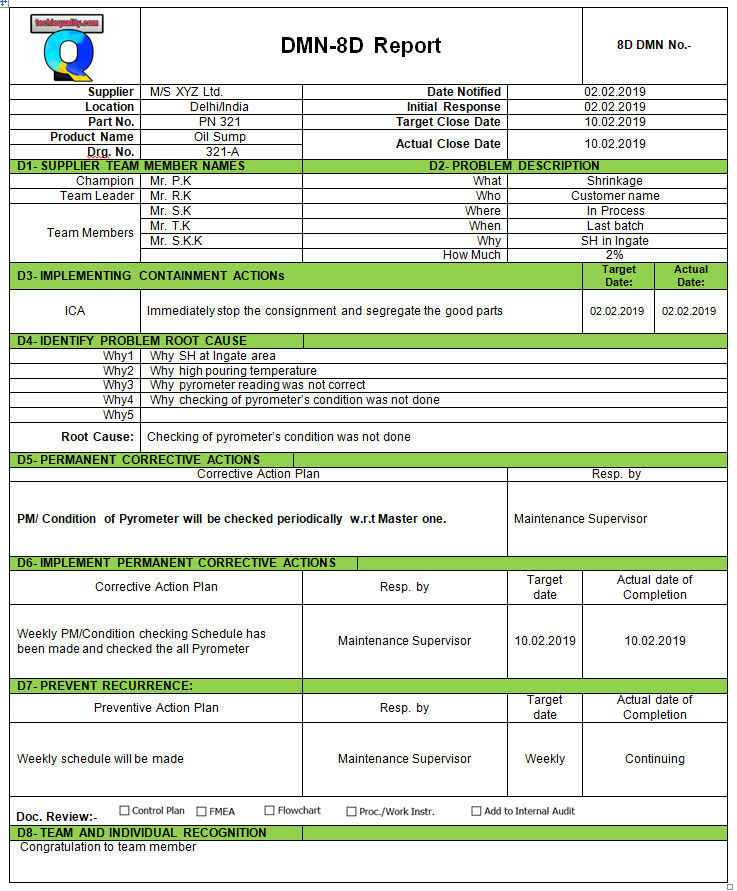

8D Report Example | Step-by-Step Guides: Example-1: There is a Customer Complaint i.e. Shrinkage on the Sump (Automobile casting part). And we have done the case study of said customer complaint and filled up the 8D template. Details are illustrated below

Case Study 1: Ingate Shrinkage (Casting)

EXAMPLE: Shrinkage Defect (Casting):

D1- SUPPLIER TEAM MEMBER NAMES: Champion name, Team Leader name, and Team Member name.

D2- PROBLEM DESCRIPTION e.g. Shrinkage Defect.

| What | Shrinkage |

| Who | Customer name |

| Where | In Process |

| When | Last batch |

| Why | SH in Ingate |

| How Much | 2% |

D3- IMPLEMENTING CONTAINMENT ACTION:

| Target date | Actual date | |

| Immediate stop the consignment & segregate good parts | 2.2.19 | 2.2.19 |

D4- IDENTIFY PROBLEM ROOT CAUSE:

| Why1 | Why SH at Ingate area |

| Why2 | Why high pouring temperature |

| Why3 | Why pyrometer reading was not correct |

| Why4 | Why checking of pyrometer’s condition was not done |

| Why5 |

| Root Cause | Checking of pyrometer’s condition was not done |

D5- PERMANENT CORRECTIVE ACTIONS:

| Corrective Action Plan | Resp. by |

| PM/ Condition of Pyrometer will be checked periodically w.r.t Master one. | Maintenance Supervisor |

D6- IMPLEMENT PERMANENT CORRECTIVE ACTIONS:

| Corrective Action Plan | Resp. by | Target date | The actual date of Completion |

| A weekly PM/Condition checking Schedule has been made and checked all Pyrometer | Maintenance Supervisor | 10.02.2019 | 10.02.2019 |

D7- PREVENT RECURRENCE:

| Preventive Action Plan | Resp. by | Target date | The actual date of Completion |

| A weekly schedule will be made | Maintenance Supervisor | Weekly | Continuing |

D8- TEAM AND INDIVIDUAL RECOGNITION: Congratulations to the team member.

In the first case study, we have discussed in ingate shrinkage of the sump and filled up all the analysis in 8D-Template, and now, we are going to discuss another case study i.e. CS No-2, details of the analysis are illustrated below.

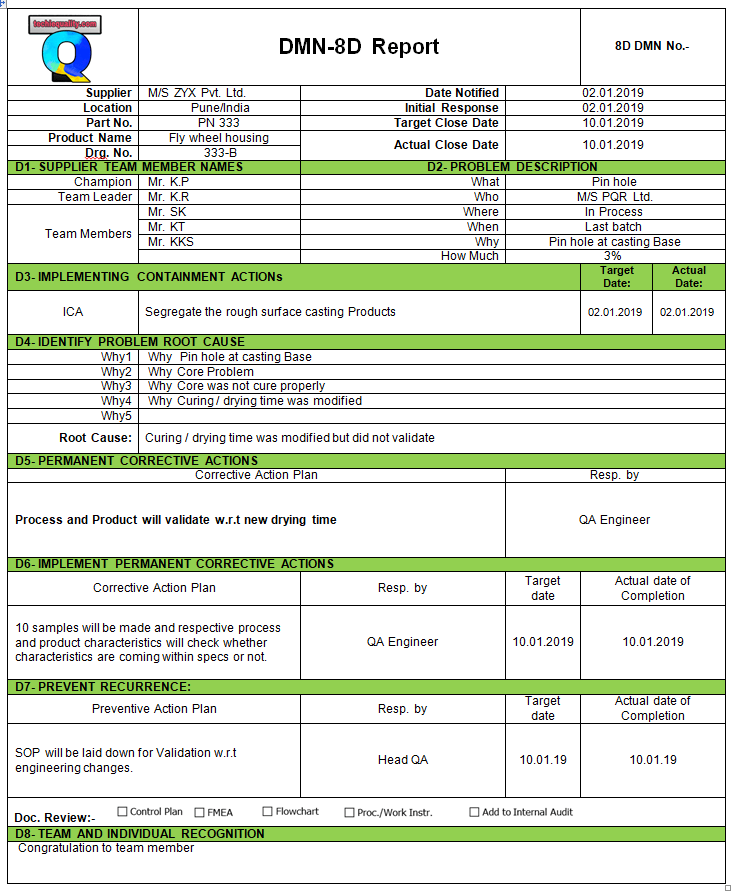

Case Study 2: Pin-hole Defects (Casting)

A Company PQR Ltd found nearly 3% of the last batch of BOP items as defective after machining operation due to a pinhole defect in casting. So the purchase head decided to ask and submit the full analysis of the said problem to their supplier in the 8D report. The same Analysis is illustrated below.

EXAMPLE: Pin-hole Defects (Casting)

D1- SUPPLIER TEAM MEMBER NAMES: Champion name, Team Leader name, and Team Member name.

D2- PROBLEM DESCRIPTION e.g. Pin-hole Defect.

| What | Pin-hole |

| Who | M/S PQR Ltd |

| Where | In-process |

| When | Last batch |

| Why | Pin-hole at casting base |

| How much | 3% |

D3- IMPLEMENTING CONTAINMENT ACTION:

| ICA | Segregate the defective part (pin-hole defect) |

D4- IDENTIFY PROBLEM ROOT CAUSE:

| Why-1 | Why pin-hole? |

| Why-2 | Why the core problem? |

| Why-3 | Why core was not cured properly? |

| Why-4 | Why the curing/drying time was not modified? |

| Why-5 |

| Root Cause | Curing/drying time was not validated |

D5- PERMANENT CORRECTIVE ACTIONS:

| Corrective action plan | Resp. by |

| Process and product will validate w.r.t new drying time | Process QA Engineer |

D6- IMPLEMENT PERMANENT CORRECTIVE ACTIONS:

| Corrective action plan | Resp. by | Target date | Actual Date |

| 10 samples will be made & respective process & product characteristics will be checked whether the characteristics are meeting the specifications or not. | Process QA Engineer | xx/yy/2020 | xx/yy/2020 |

D7- PREVENT RECURRENCE:

| Preventive action plan | Resp. by | Target Date | Actual Date |

| Validation process SOP will be made including change control | QA.Engineer | xx/yy/2020 | xx/yy/2020 |

D8- TEAM AND INDIVIDUAL RECOGNITION: Congratulations to the team member.

QA/QC/TQM/Lean/QMS/6-Sigma Template or Format:

FAQ:

What is 8D in quality?

The 8D is eight disciplines of problem-solving, these are mainly, 1-supplier team member names, 2-problem description, 3-implementing containment action, 4-identify problem root cause, 5-permanent corrective actions, 6-implement permanent corrective actions, 7-prevent recurrence, 8-team, and individual recognition.

What are the 8 disciplines of an 8D-DMN report?

The 8D has 8 nos disciplines which makes it a systematic way to resolve the problem and the disciplines are

- Team Formation or Establishing the team or creating a team.

- Problem Description or defining the problem.

- Implementing containment actions or Interim action.

- Identify the problem’s root cause or RCA.

- Developing permanent corrective actions or corrective action

- Implementing permanent corrective actions or implementing & validating corrective actions

- Preventing reoccurrences or preventive actions

- Congratulate the team or Team & individual recognition.

The 8D-DMN is a very popular methodology that is frequently used in manufacturing industries to resolve the notified defective material in all the stages including customer complaints as well. we have already discussed two no case studies or practical manufacturing examples for a better understanding of the concept, application, and thorough knowledge of 8D template or format.

This concept enhances your depth of knowledge on 8D and its principles on how to fill up the template or format, which is described above. After doing so your confidence in 8D activities for internal application and for application on customer complaints will be enhanced.

Useful Post

QA Excel Template | Top Skills of Quality Assurance Engineer

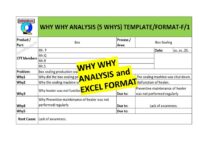

5 Whys Excel Template , Download why why analysis excel format

What is Quality 4.0 | What Type of Skill Set Needs to be Developed as an Employee

Why Why Analysis | Template | 5 Why Analysis Method with Manufacturing Examples

Normal Distribution Probability Formula, Calculation & Manufacturing Examples

More on TECHIEQUALITY

Thank you for reading…….Keep visiting Techiequality.Com

Popular Post