Corrective Action vs Preventive Action

Corrective Action vs Preventive Action

Hi readers! Today we will discuss an important topic which is Corrective Action vs Preventive Action. The terms Corrective Action and Preventive Action are the most popular terminology in the manufacturing industry. But now in the new business system standard, the preventive action is expressed through the use of risk-based thinking. It means preventive action is replaced by Risk and opportunity. Here we will discuss the definition of Corrective action and preventive action with industrial examples.

CAPA Process/ CAPA Concept w.r.t ISO 9001 and IATF 16949.

Corrective Action vs Preventive Action:

Correction: Action to eliminate the symptom of problems.

Corrective Action:

- Action to eliminate the cause of non-conformity in order to prevent a recurrence.

- Definition 2-Action to eliminate the Root cause of Problems.

- Action taken in order to eliminate the root cause.

Preventive Action:

- Action to eliminate the cause of potential nonconformities in order to prevent their occurrence.

- Definition2.-Action to eliminate the potential cause of problems

- Action taken in order to avoid root cause recurrence

Example1-

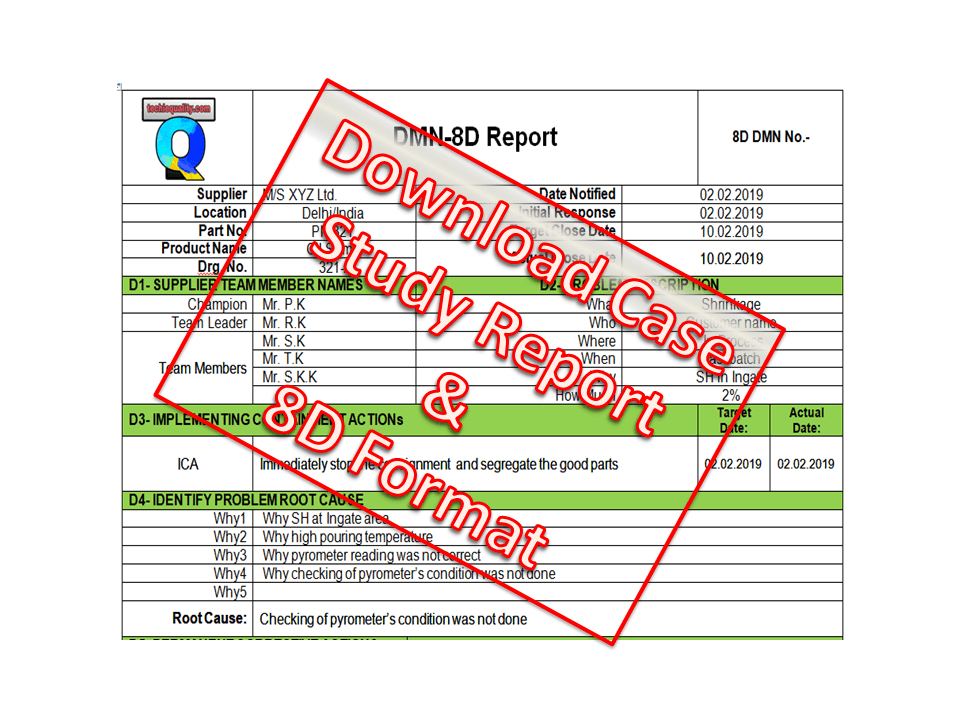

The XYZ Pvt Ltd Company manufactures Oil sump. But 2% of castings were rejected at the customer end due to shrinkage. So the purchasing department asked the supplier to submit the 8D report and CAPA Report. After getting the Customer Complaint. The Process Engineer of the Supplier started the Rejection investigation and finally prepared the CAPA Report;

Correction: Segregated the Casting and stopped the consignment of the same batch of products.

Corrective Action:

Problem- Shrinkage.

Why-why Shrinkage? Ans. Shrinkage was found at the In-gate of Casting so the process engineer thought that the wrong gating system may be a potential cause for in-gate shrinkage. And he started to recheck the in-gate system.

Why-why in-gate Shrinkage? Ans. The gating system was modified but validation was not done.

Why- Why gating system validation was not done?

Ans. – The production Manager has scheduled the same product for the Next day of modification without the validation of the tool.

Why- why validation is not done timely?

Ans. – There was no comprehensive Production planning.

Corrective Action: Comprehensive Production planning will be prepared considering with tools status.

Preventive Action: Tools Status will update periodically.

I hope this example is helpful to you to understand the difference between Corrective Action vs Preventive Action.

Useful Articles:

“Should you need any further information, please do not hesitate to comment below”.

Thank you for Reading…Keep Visiting Techiequality.Com

Popular Post: