5W1H Analysis Example |Download Template

Last updated on November 16th, 2024 at 08:51 am

5W1H Analysis Example |Download Template:

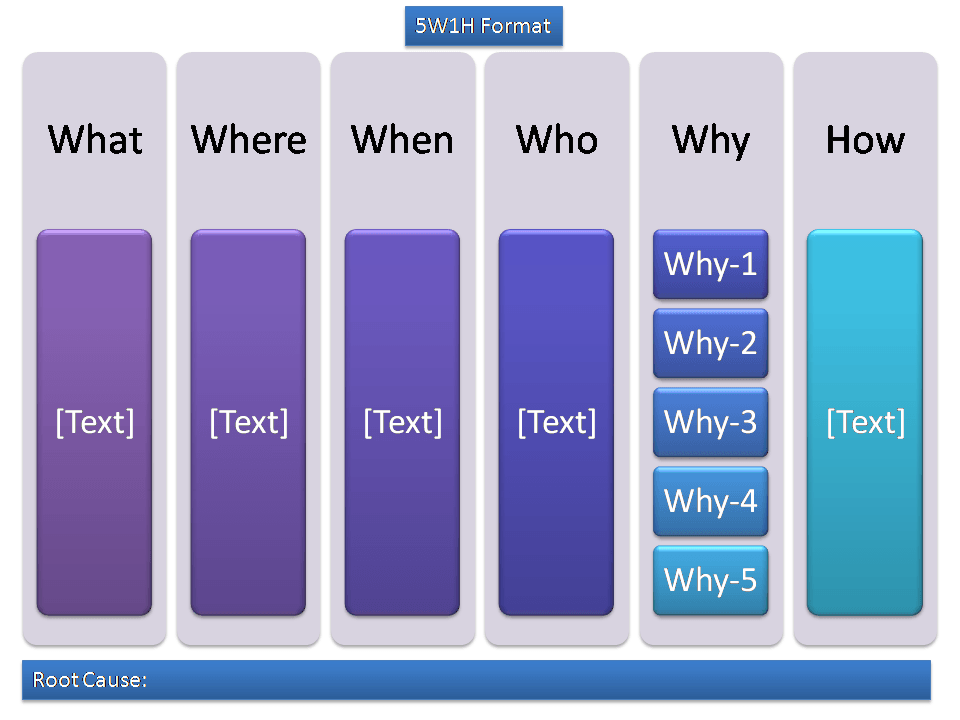

Hi Readers! Today we will discuss here 5W1H Analysis with a manufacturing example. 5W1H is a methodology consisting of six questions as What? Where? When? Who? Why? How? Needs to ask a lot of questions to collect all the necessary data to draw up a report of the existing situation with the aim of identifying the phenomenon of the problem. Go through the below details of the 5W1H Analysis Example (Manufacturing Example).

DOWNLOAD-5W1H Template/ Format.

5W1H Analysis:

5W1H Analysis will help you broadly to know the nature of the problem like What is the Problem? Where did the problem occur? When did the problem happen? Who do you need to get involved? Why is it happening? How can you overcome the Problem?

The above pattern may be subject to change if it does not fit with the scenario/ nature of the problem. We can use “how much” additionally as and when applicable regarding the nature of the problem. And then it’s namely called 5W2H. Here, we will illustrate only 5W1H.

Description of 5W1H:

| Phenomenon of Problem: | Explanation: |

| What is the Problem? | Where did the problem occur? |

| When did the problem happen? | Describe the location, place, and m/c involved. |

| Who do you need to get involved? | Find out the time when a situation took place. |

| Involvement of people, external providers, etc. | Why is it happening? |

| How can you overcome the problem? | To know the reason behind of facts |

| Method of implementation, deployment, etc. | Method of implementation, deployment, etc. |

Benefits of 5W1H Method:

- It can apply to all types of industries.

- One can use it to address all kinds of problems to ask questions from every angle.

- It’s a simple method, that everyone can understand, no need for training to ask these types of questions.

You could also like to read the below Articles:

The Process Approach to QMS (ISO 9001, IATF 16949).

7 principles of QMS | Quality Management Principles.

SPC Format |DOWNLOAD Excel Template of SPC Study

7QC Tools Excel Template |DOWNLOAD Format.

How to measure process capability (Cp & Cpk)? Download Excel Template.

How to measure process performance (Pp & Ppk)?

How to apply 5W1H method in Industries?

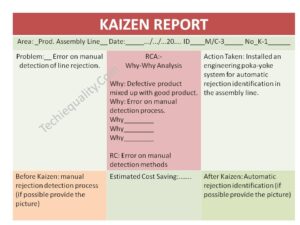

From my past experience, I’m trying to share how I was involved with Gemba’s investigation of the line rejection problem. I often use the 5W1H and 5W2H methodology to collect the information on line rejection, before doing the brainstorming, our team members collect the information about the problem with details like which machine, which place, who is responsible, etc. so that we can get the complete data and information for root cause analysis. One day during the line product checking, we found 5 products were rejected. so next I collected the whole data and informed to our CFT team for analysis, Thereafter I realized that how this (5W1H methodology) is helpful. Below is the step-by-step approach described for the deployment of the 5W1H method in industries.

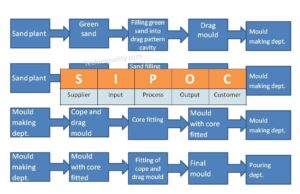

In Manufacturing Industries, this 5W1H format is generally used for problem-solving and It’s widely used during shop floor red bin analysis and also, it’s utilized for analysis of different types of problems like machine breakdown, process-related issue, man-related issues, material related issues, utility breakdown, tools related issue, mechanical & electrical related breakdown, etc.

Step by step approach:

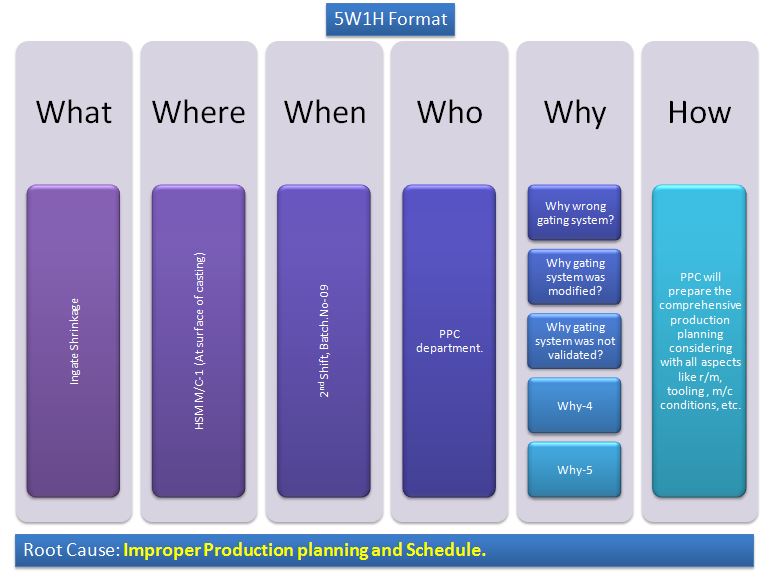

- The 5W1H method is applicable to address all kinds of Problems, so go to the real place where the problem occurred. Understand and write in the first “W” that, what is the problem, e.g. Ingate shrinkage, write the technical definition and details of the problem with the defective product picture.

- The second process is to cover the question related to “W-2” i.e (Where), Now we have to mention the process area, the machine no, defect location in the product, here we have to cover the defect’s generation area/ process, where it actually generated.

- The third “W” is When, here you have to investigate the shop floor workforce and to check the relevant data to know the time/ period/ date/ shift, etc. that when the problem occurred.

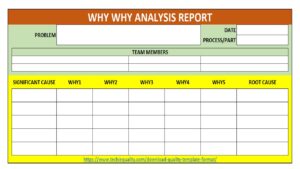

- Now we will discuss “Why” This is an important process where we have to analyze the root cause of the problem by using a why-why methodology.

- In the step “HOW” we have to take an action plan against the root cause.

- This is the last step i.e. “Who”: who is the responsible person to implement the action plan.

5W1H Analysis Example-1:

We have taken the same example here, which is already explained in previous articles. If you have not yet read then kindly go through it-previous article.

According to previous article the problem found in the process was Ingate Shrinkage. And same we are going to explain it through the 5W1H template.

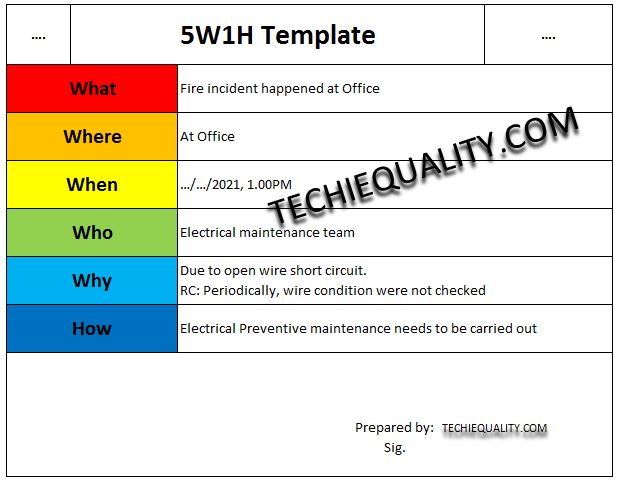

EXAMPLE-2:

The cross-functional team has investigated the fire incident, which was happened in the office at 1.00PM. They have recorded the information in 5W1H format, the same as we have mentioned in below.

QA/QC/TQM/Lean/6-Sigma Template or Format:

Useful Articles:

Sales vs Marketing |Top-5 Marketing Issue SWOT Analysis.

Repeatability vs Reproducibility | Discussion of Key difference.

Verification vs Validation | What is difference between verification and validation?

Kaizen vs Innovation | Key Differences between Kaizen and Innovation

Corrective Action vs Preventive Action

FAQ:

What is the difference between 5W1H and 5W2H?

the main difference is the absence of 2H i.e. “How much” in the 5W1H methodology, otherwise all terms are the same in both 5W1H and 5W2H. but sometimes we use “how much” in place of “How” as per the nature of the problem in the 5W1H template

More on TECHIEQUALITY

Thank you for reading…Keep visiting Techiequality.Com

Popular Post: