4M Checklist Template | Free Download Format

Last updated on November 16th, 2024 at 08:47 am

4M Checklist Template |Free Download Format:

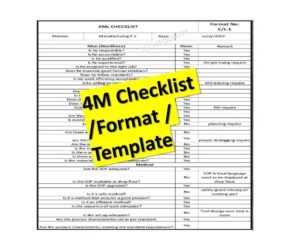

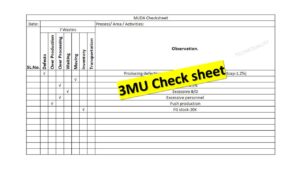

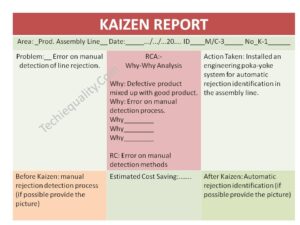

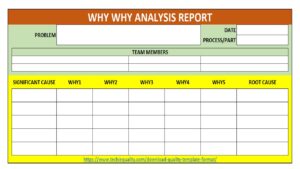

Hi Readers! Today we will discuss here on 4M Checklist Template. Generally, the 4M concept is used in several methodologies, In the Cause and effect diagram it represents the potential causes and similarly, it is also used as a checklist for Kaizen. In the kaizen approach, there are some checklists used as [1] 5MUs checklist [2] 5W1H checklist [3] 4M Checklist. But here we will only explain on the 4M checklist. We have prepared the 4M checklist for your ready reference. You can easily download this checklist/check sheet from the below link.

DOWNLOAD-4M Checklist/Check-sheet / 4m analysis template excel

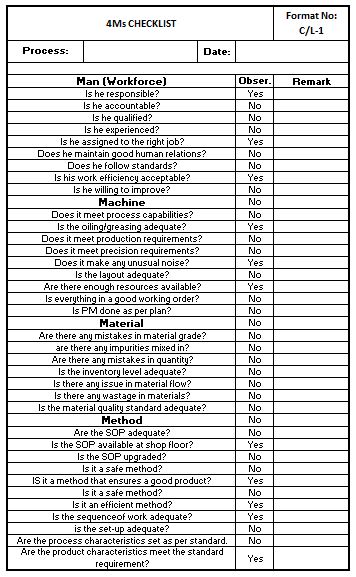

Sample 4M Checklist Copy:

4M Checklist Template:

4M i.e. Men, Machines, Materials & Methods are the common aspects and important for quality improvement and KAIZEN. Questions to be asked related to 4M to implement kaizen activities effectively are;

| Man (Workforce) |

| Is he responsible? |

| Is he accountable? |

| Is he qualified? |

| Is he experienced? |

| Is he assigned to the right job? |

| Is everything in a good working order? |

| Does he follow standards? |

| Is his work efficiency acceptable? |

| Is he willing to improve? |

| Machine |

| Does it meet process capabilities? |

| Is the oiling/greasing adequate? |

| Does it meet production requirements? |

| Does it meet precision requirements? |

| Does it make any unusual noise? |

| Is the layout adequate? |

| Are there enough resources available? |

| Are there any mistakes in the material grade? |

| Is PM done as per plan? |

| Material |

| Is there any issue with material flow? |

| Are there any impurities mixed in? |

| Are there any mistakes in quantity? |

| Is the inventory level adequate? |

| Is there any wastage of materials? |

| Is the material quality standard adequate? |

| IS it a method that ensures a good product? |

| Method |

| Is the SOP adequate? |

| Is the SOP available on the shop floor? |

| Is the SOP upgraded? |

| Is it a safe method? |

| Is the setup adequate? |

| Is it a safe method? |

| Is it an efficient method? |

| Is the sequence of work adequate? |

| Are there any mistakes in the material grade? |

| Are the process characteristics set as per standard? |

| Are the product characteristics meeting the standard requirement? |

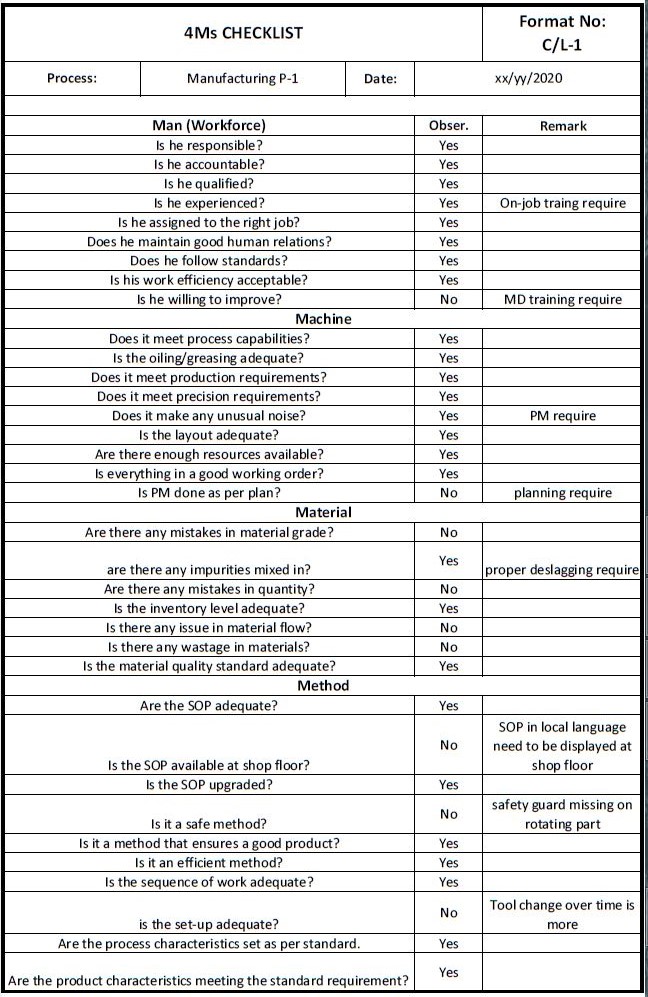

Example: We had audited the manufacturing process and got the below observations;

During the process audit through the 4M checklist, we have observed so many improvement points, these are mentioned in the above checklist remark column. In this way, you can easily find out the process improvement points. Download the above 4M Checklist and try to customize it according to your manufacturing process.

How to Implement the 4M checklist /Check sheet in Manufacturing Industries?

I always try to share my own industrial experience so that my readers can easily understand, learn, and implement the skill-based concept in their operational process.

Posts/articles on this website are skilled base, you can read our articles for your personal learning, for training purposes, and for practical implementation in the industry as well.

Generally, we use the 4M, and 6M check sheets to audit /investigate and to check the condition and lacking points of 4M factors (Men, Machine, Method, and Material). Some industries plan the checking schedule on a weekly and some on a monthly basis as per the production plan. By doing so we can easily maintain the machine condition, reduce the B/D, Increase the machine run time, we can identify the on-job training of operators /workers, maintain the material inventory, monitor the effectiveness of the Method, we can further improve our process, etc.

Below are the steps for implementation of 4M checklist/ check sheet:

- Prepare the 4M checklist /Check sheet as per your Process in detail considering with past 6 months’ quality defect causes, B/D nature causes, customer complaints, etc.

- Define the Checking plan (e.g. weekly, monthly, etc.)

- Check 4M factors by using the 4M check sheet as per your plan,

- Write the observations.

- Discuss with the concerned department and formulate the Action plan / CAPA.

- Implement the CAPA /Action Plan.

- Monitor the implementation of the action plan (For example, verify it in the next checking).

4M Change Management:

After doing the 4M Audit you can easily identify the 4M-related changes. the above 4m checklists is mentioned for your reference but the checking points are not limited. you can customize the above checklist as per your manufacturing process.

You can identify and monitor the 4M changes in the 4M change Record sheet as per below.

| Sl. No. | Process | Type of Change | Nature of Change | Details of Change | Action Taken | Set-up Approval | Retroactive check | Containment Action |

Example:

Type of Change: Man, Machine, Method, and Material.

Nature of Change: Plan change, Unplan change, Abnormal change

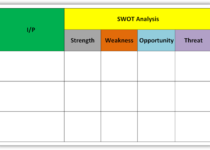

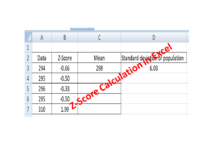

QA/QC/TQM/Lean/6-Sigma Template or Format:

FAQ (Frequently Asked Question):

What is 4M in Manufacturing Industries?

Ans.: In Industries the term 4M is generally used as [1] Man [2] Machine [3] Material & [4] Method.

What is 4M method?

Ans.: The 4M method is generally used in manufacturing industries for problem-solving /analysis. These terms are generally represented in 4M change management and also in the Cause and effect diagram or Fishbone diagram. The potential causes are basically represented under the category of 4M- Cause and effect diagram for further processing like causes/problem analysis and validation of causes, etc.