C Chart Excel Template | Formula | Example | Calculation

Last updated on October 5th, 2024 at 10:01 am

C Chart Excel Template| Formula |Example |Calculation:

Hi Readers! Today, we will be discussing here on attribute type SPC chart i.e. C chart. Its formula, calculation, and industrial example. The C chart is also called the number of nonconformities chart. Where the sample size is constant. Read the below description to learn about its selection and application in industries. If you are interested in downloading the sample C Chart Excel Template then, click on the given below link.

Sample C Chart Excel Template with industrial example-Download.

Number of nonconformities chart (C Chart):

The C chart, attribute type SPC control chart, or the number of nonconformities chart is generally used to identify the common or special causes present in the process and is also used for monitoring and detecting process variation over time. It helps to determine whether the process is in a state of statistical stable or not. Overall, it indicates that special causes are present in the process or not, whether the process is under control or not, and process variability. This C chart is selected when there is a constant sample size and multiple defects per unit are present.

Selection of Attribute type SPC Control chart (C Chart):

Step-1: Data Types?

Condition: – Discrete type data (Attribute type data)

Step-2: Is the interest in nonconformities or multiple defects per unit?

Condition: – yes, multiple defects per unit

Step-3.:- Is the sample size constant?

Condition: – Yes, then use the C chart.

| Description | Condition |

| Data Type: | Discrete type data (Attribute type data) |

| Is the interest in nonconformities or multiple defects per unit? | Yes, Multiple defects per unit present |

| Is the sample size constant? | Yes |

| Chart type: | C Chart |

C Chart Formula:

The three important things need to be calculated before plotting the C chart i.e. [1] Centerline, [2] Upper control limit, & [3] lower control limit.

Centerline (CL) or C bar = Total number of nonconformities or defects / Number of samples

Upper control limit (UCL) = C-bar + 3 x Square root of C-bar

Lower control limit (LCL) = C-bar – 3 x Square root of C-bar

| The formula of C chart | |

| CL or C- bar = | Total number of nonconformities or defects / Number of samples |

| UCL = | C-bar + 3 x Square root of C-bar |

| LCL = | C-bar – 3 x Square root of C-bar |

How to plot a c chart in excel?

Here, I’m going to share my own industrial experience regarding the application and usage of a c chart in the manufacturing industry by providing a sample example for your quick learning and implementation in your organization. I have considered 50 sample sizes, and three different defects and collected the data for 30 days. Details of data are given below table.

| Date | Constant sample size (n) | Defect-1 | Defect-2 | Defect-3 | Total Defects |

| 1 | 50 | 1 | 1 | 2 | |

| 2 | 50 | 1 | 1 | 2 | 4 |

| 3 | 50 | 2 | 2 | 1 | 5 |

| 4 | 50 | 1 | 1 | 2 | |

| 5 | 50 | 1 | 1 | 2 | 4 |

| 6 | 50 | 1 | 1 | 2 | |

| 7 | 50 | 1 | 1 | 1 | 3 |

| 8 | 50 | 2 | 2 | 2 | 6 |

| 9 | 50 | 2 | 2 | 3 | 7 |

| 10 | 50 | 1 | 1 | 2 | 4 |

| 11 | 50 | 1 | 1 | 3 | 5 |

| 12 | 50 | 1 | 1 | 1 | 3 |

| 13 | 50 | 5 | 5 | 7 | 17 |

| 14 | 50 | 1 | 1 | 2 | |

| 15 | 50 | 1 | 1 | 1 | 3 |

| 16 | 50 | 2 | 2 | 1 | 5 |

| 17 | 50 | 1 | 1 | 2 | |

| 18 | 50 | 1 | 1 | 1 | 3 |

| 19 | 50 | 1 | 1 | 3 | 5 |

| 20 | 50 | 1 | 1 | 2 | |

| 21 | 50 | 2 | 2 | 4 | |

| 22 | 50 | 1 | 1 | 2 | |

| 23 | 50 | 2 | 2 | 2 | 6 |

| 24 | 50 | 1 | 1 | 3 | 5 |

| 25 | 50 | 1 | 1 | 1 | 3 |

| 26 | 50 | 2 | 2 | 4 | |

| 27 | 50 | 1 | 1 | 1 | 3 |

| 28 | 50 | 1 | 1 | 2 | |

| 29 | 50 | 1 | 1 | 1 | 3 |

| 30 | 50 | 1 | 1 | 1 | 3 |

All the above three defects are attribute type defects. Before plotting the c chart in excel we have to calculate the three important things first, one is CL, UCL & LCL.

Calculation:

Centerline (CL) or C-bar:

Formula = Total number of nonconformities or defects / Number of samples

CL = 121 / 30 =4.033

UCL (Upper control limit):

Formula = C-bar + 3 x Square root of C-bar

UCL = 4.033 + 3* Square root of 4.033

UCL = 4.033+3*2.008

UCL = 10.0577

UCL = 10.058

LCL (Lower control limit):

LCL = C-bar – 3 x Square root of C-bar

LCL = 4.033 – 3* Square root of 4.033

LCL = 4.033-3*2.008

LCL = 4.033-6.024

LCL = -1.991 (the value is negative so LCL is Zero)

LCL = 0.00

| Calculation value | |

| CL = | 4.033 |

| UCL = | 10.058 |

| LCL = | 0 |

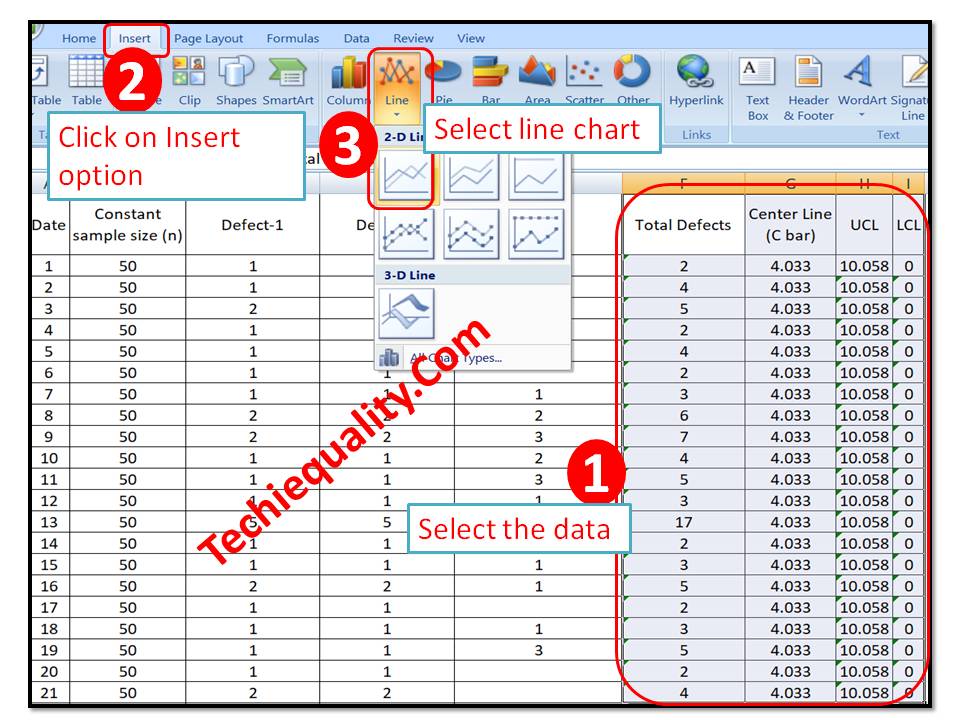

Follow the below step to plot the c chart in excel:

Step-1: open the excel sheet.

Step-2: Do the data entry on the Excel sheet.

Step-3: Select the data and then go to the insert option in the main menu and next to select line chart. The detail is mentioned in the below image.

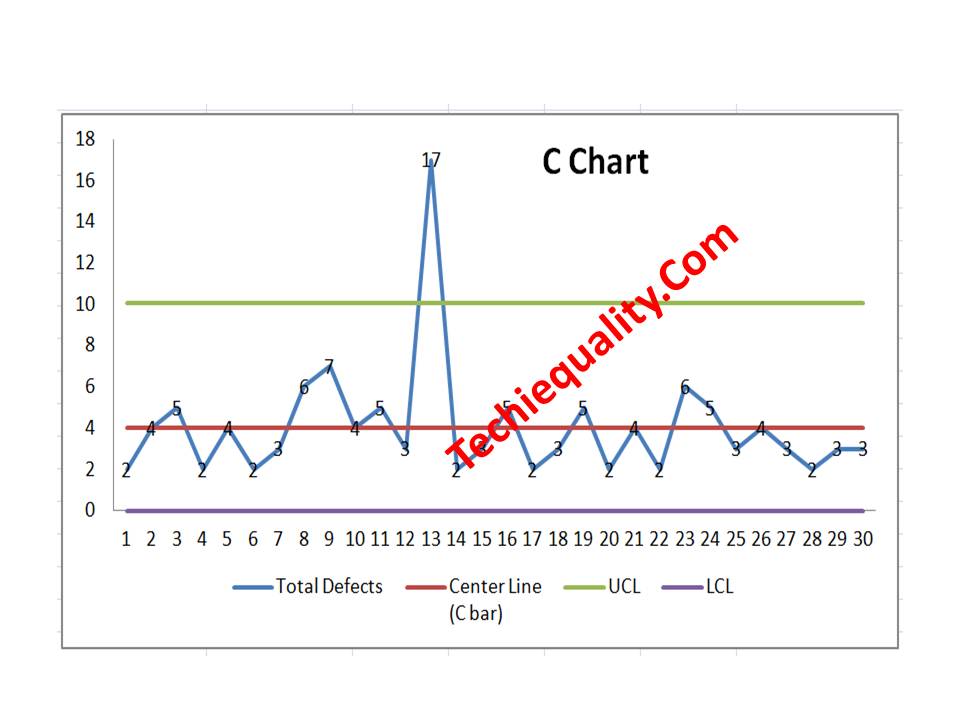

C Chart:

With the help of the above data, we have plotted the c chart, which is given below. if you would like to download the C Chart Excel Template then, click here.

Interpretation of the above C Chart:

In the above C chart, we have seen that one defect value is beyond the upper control limit. It means on day-13 special cause was present in the process, so we have to take the action on it to control the process.

Free Templates / Formats of QM: we have published some free templates or formats related to Quality Management with manufacturing / industrial practical examples for better understanding and learning. if you have not yet read these free template articles/posts then, you could visit our “Template/Format” section. Thanks for reading…keep visiting techiequality.com

Useful Post:

What is Preventive Maintenance? | Predictive Maintenance |Types & Example

Plan Do Check Act Cycle | PDCA Cycle Manufacturing Example | Implementation

Attribute MSA |How to do Attribute type MSA Study| Example |Acceptance Criteria

Gage R and R |Attribute type MSA |How to do MSA Study | Acceptance Criteria

More on TECHIEQUALITY