5W2H Analysis Example |Download 5W2H Format

Last updated on November 16th, 2024 at 08:49 am

5W2H Analysis Example |Download 5W2H Format:

Hi Readers! Today we will discuss on 5W2H Analysis Example with industrial/manufacturing practices and also in this post, you can download our approved template for deployment in your workplace. We have already posted our previous article 5W1H analysis with examples. If you have not yet read that article then first go through it. Our 5W2H template/format is ready to use just download it from given below link.

DOWNLOAD-5W2H Template.

How to use the 5W2H Method in Manufacturing Industries?

In Industry, both the 5W2H and 5W1H are frequently used methods to Understand, collect, and analyze the Problem. The application of the 5W2H method depends on the nature of the problem. The full form of 5W2H is What, Where, When, Who, Why, How, and How much. Information and Data on any problem are always required for analysis and to find out the root cause. So 5W2H Format will help you to get the collective data and information in one place for problem analysis. From my past experience, I’m sharing the approach and steps for the usage and implementation of the 5W2H methodology.

Daily we find some problem in our production process/line, to overcome such problem we have to resolve these as soon as possible. The problems may be maintenance-related (like Breakdown, equipment failure, utility problems, quality issues, etc.). To understand and solve the problem, we need info. and data. In my point of view, always problem-solving team should always visit the Gemba ( Actual place) to clearly understand and investigate the problem. Below are the steps that we generally were being followed;

- Visit to the Gemba (E.g.-Shop floor)

- Ask the question to the operator /shop floor person and collect the information and data.

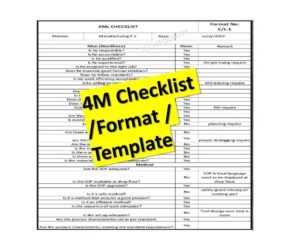

- Investigate the 4M or 6M (Men, M/C, Material, Method, Mother Nature, and Measurement) factors and see if any clues are present or not.

- Do Brainstorming and find out the Root Cause.

The Manufacturing Example is mentioned below covering all the above steps.

5W2H Analysis:

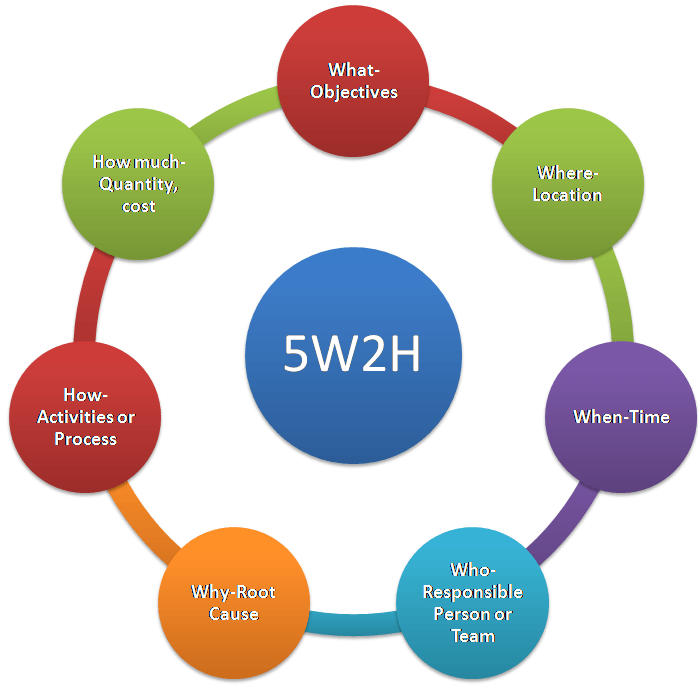

5W2H Analysis will help you broadly to know the nature of the problem like What is the Problem? Where did the problem occur? When did the problem happen? Who do you need to get involved with? Why is it happening? How can you overcome the Problem? How much quantity?

The above pattern may be subject to change if it does not fit with the scenario/ nature of the problem. We can use only “how” as and when applicable regarding the nature of the problem. And then it’s namely called 5W1H. Here. Today in this article we will discuss only 5W2H Analysis with examples.

Explanation of 5W2H:

| 5W2H terms | The Phenomenon of the Problem: | Explanation: |

| What | What is the Problem? | Goal or Objectives (To describe the problem, activity, task, or project purpose) |

| Where | Where did the problem occur? | Location (Describe the location, place, and m/c involved) |

| When | When did the problem happen? | Time (Find out the time, date, and schedule when the situation took place) |

| Who | Who do you need to get involved with? | Responsible Person or Team (Involvement of people, external provider, etc.) |

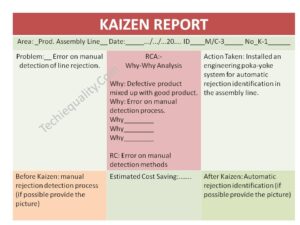

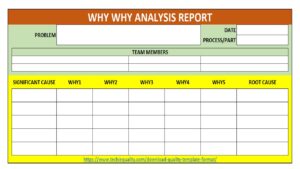

| Why | Why is it happening? | Root Cause (To know the reason behind facts, popular tools used for root cause finding are, e.g. RCA, why-why analysis, etc.) |

| How | How can you overcome the problem? | Activities or Process (Method of implementation, deployment, etc.), e.g. CAPA. |

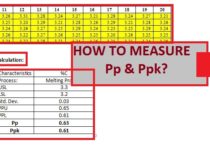

| How Much | How much quantity? | Cost, Quantity, etc. |

The above phenomenon of question is not always common for all scenarios; the question patterns will be changed according to the nature of issues/problems/risks/opportunities.

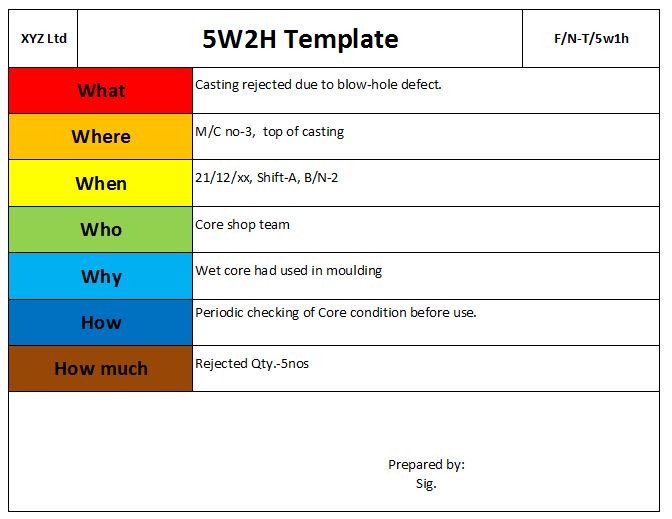

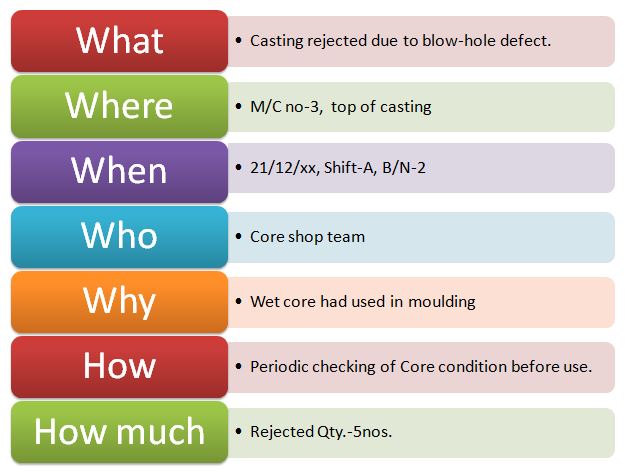

EXAMPLE-1:

During shop floor rejection analysis at the rejection yard, we found 5 nos casting were rejected due to a blow-hole on the top surface. Same we have explained through the 5W2H format as;

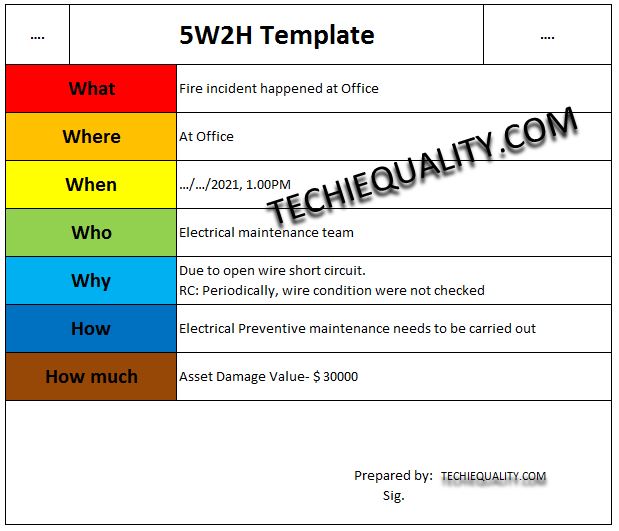

EXAMPLE-2:

Unfortunately, one day at 1.00 PM, a Fire incident happened at the office. The organization had taken the necessary immediate action during the incident but later the CFT team investigated the area to collect the data for root cause analysis. They have recorded the data and analysis report in 5W2H Format, the same format is given below.

QA/QC/TQM/Lean/6-Sigma Template or Format:

FAQ:

What is the difference between 5W2H and 5W1H?

the main difference is the absence of 2H i.e. “How much” in the 5W1H methodology, otherwise all terms are the same in both 5W1H and 5W2H. but sometimes we use “how much” in place of “How” as per the nature of the problem in 5W1H format.

What is the meaning of 5W2H?

The methodology itself indicates that there are 5 Ws and two Hs. This means, what, where, when, who, why, how, and how much. it’s a questioning method and very easy to implement in any organization. we have already given multiple examples for your better understanding. and also defined each term of 5W2H in the above table. just think of one more example of a machine breakdown issue on the shop floor. and you are trying to solve it in a systematic way by applying the 5W2H methodology. Once you applied it and resolved the problem then simultaneously, you did both jobs i.e. one is a record of b/d CAPA and solved the actual problem. It’s a very useful record and you can refer to it when there is the same problem occurs on the same machine.

More on TECHIEQUALITY

Thank you for reading…keeps visiting Techiequality.Com

Popular Post: